digital coriolis meter installation company for life sciences

What is a Mass Flow Controller? A coriolis mass flow controller automatically controls the flow rate of a gas according to a set flow rate sent as an electric signal, without being affected by use conditions or changes in gas pressure. Flow rates can be roughly classified into two types: volumetric flow and mass flow.Thermal MFCs are both accurate and repeatable, precisely controlling gas flows between 2 and 100% of their Full Scale reading with a resolution of 0.1%.

Features of mass flow meter controller:

Simultaneously displays Mass Flow, Volumetric Flow, Pressure and Temperature.

Two programmable mass flow rate totalizers.

High, Low or In Range Alarms with preset action delay for Mass Flow, Temperature and Pressure.

Multi-Gas functionality: support for 90 different gases and gas mixes.

“User Defined Mixture” functionality allows to create and store up 20 custom gas mixes with up to 5 different gases each.

User programmable mass flow rate Pulse Output

All 3 user selectable analog input and output interfaces are standard: 0-5Vdc, 0-10Vdc, 4-20mA.

Two user selectable digital communication interfaces are standard.

Optional Modbus RTU network interface with isolated RS485 transceiver.

User programmable solid state relay with latch option.

Universal 12-26 Vdc power supply input.

Free, easy-to-use configuration and calibration software

Programmable set point table with ramping up/down capability up to 16 steps.

What are the main components of mass flow controller?

All mass flow controllers have several common components—an inlet port, an outlet port, a mass flow sensor, a proportional control valve, and a closed loop control system.

How does a mass flow controller work?

A thermal mass flow controller is a compact device that precisely dispenses gaseous or liquid chemicals into a process. Flow rate can be set electronically by a voltage, current or digital (fieldbus) source, and measured by an internal sensor. When the measurement value matches the setpoint value, the control valve adjusts to allow the correct amount of substance to pass through by modulating the size of its passage.

This system consists of a mass flow meter (the sensor) combined with a control valve and feedback electronics between the sensor and the valve. A PID (proportional-integral-derivative) control function is often included as part of the device electronics, but its characteristics can be adjusted by the user for fast or smooth control.

Why would you control mass flow instead of volume flow?

The main variable in many research and production processes is mass, not volume. Coriolis flow controller are able to control mass flow directly. A gas or liquid's mass is an independent value economically, regardless of the operating temperature or pressure. In this way, mass flow devices are not affected by fluctuations in incoming flow pressure and temperature.

To meet users' preferences for expressing compressible gas flow as volume flow anyway, conditions are agreed upon under which mass flow is converted into volume flow. In the unit of volume used, the subscript "n" indicates a temperature of 0 °C and a pressure of 1 atm, which are the ‘normal’ reference conditions.

What is the difference between a mass flow controller and a mass flow meter?

The main difference between a Mass Flow Meter (MFM) and a Mass Flow Controller (MFC) is that an MFM simply measures the gas flow passing through the device. It is ostensibly a sensor. However, an MFC not only measures the gas passing through the device but it also controls it.

Technical Data for G C -Series Mass Flow Controllers

0.5sccm – 6000 slm Full Scale

Standard Specifications (Contact for available options.)

Performance | GC -Series Mass Flow Controller |

Accuracy at calibration conditions after tare | ± 1% of Full Scale |

High Accuracy at calibration conditions after tare | ±0.5% of Full Scale High Accuracy option not available for units ranged under 5 sccm or over 3000 slm |

Repeatability | ± 0.2% Full Scale |

Zero Shift and Span Shift | 0.2% Full Scale / ºCelsius / Atm |

Operating Range / Turndown Ratio | 2% to 100% Full Scale / 50:1 (100:1 optional) |

Maximum Controllable Flow Rate | 100% Full Scale |

Maximum Measurable Flow Rate | 100% Full Scale |

Typical Response Time | <1000 ms |

Leakage Rate | 1×10-9 atm ·cc/s He |

Operating Conditions | GC -Series Mass Flow Controller |

Mass Reference Conditions (STP) | 25ºC & 14.696 psia (standard — others available on request) |

Operating Temperature | 0 to +50 ºCelsius |

Humidity Range (Non–Condensing) | 0 to 90% |

Maximum Internal Pressure (Static) | 145 psi(g)/10bar(g) optional:Max.435psi(g)/30bar(g) |

Pressure Differential (Inlet to Outlet) | Under 500slm:72.5psi(d)/5bar(d); Above 500slm:145psi(d)/10bar(d) |

Mounting Attitude Sensitivity | Full Scale:None |

Valve Type | Normally Closed |

Ingress Protection | IP40 |

Wetted Materials | 316L 417J1 Stainless Steel, Viton, Heat Cured Silicone Rubber, Glass Reinforced Polyphenylene Sulfide, Heat Cured Epoxy, Aluminum, Gold, Brass, Silicon, Glass. If your application demands a different material, please contact . |

Communications / Power | GC-Series Mass Flow Controller | |

Monochrome LCD or color TFT display Integrated multifunction button | Display Mass Flow, Cumulative Flow, conversion gas coefficient and other functions | |

Digital Communications Options1 | RS-232 Serial / RS-485 Serial / Modbus RTU / PROFIBUS / EtherNet/IP / DeviceNet / Modbus TCP/IP / EtherCAT / PROFIBUS-DP | |

Analog Signal2 Options | 0-5 Vdc / 1-5 Vdc / 0-10 Vdc / 4-20 mA | |

Optional Secondary Output Signal2 | 0-5 Vdc / 1-5 Vdc / 0-10 Vdc / 4-20 mA | |

Electrical Connection Options | 9-pin D-sub (DB9) / 15-pin D-sub (DB15) / RJ11 | |

Supply Voltage | 24 Vdc / ±15Vdc | |

Supply Current | under 500slm : 0.50 Amp; above | 500slm:1 .0Amp |

1. The Digital Output Signal communicates Mass Flow, Cumulative Flow. 2. The Analog Output Signal and Optional Secondary Analog Output Signal communicate your choice of Mass Flow, Cumulative Flow. | ||

Features | GC-Series Mass Flow Controller |

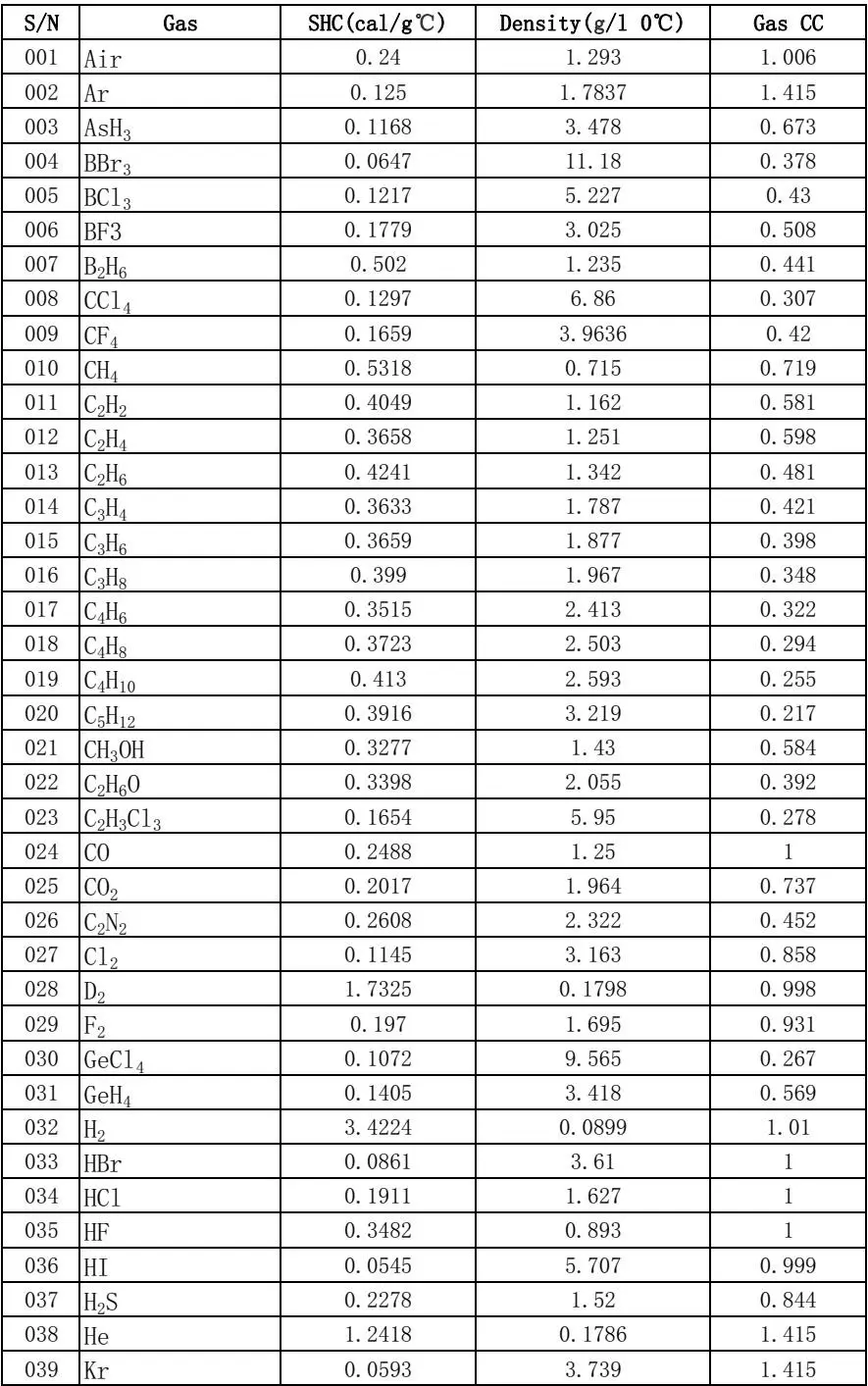

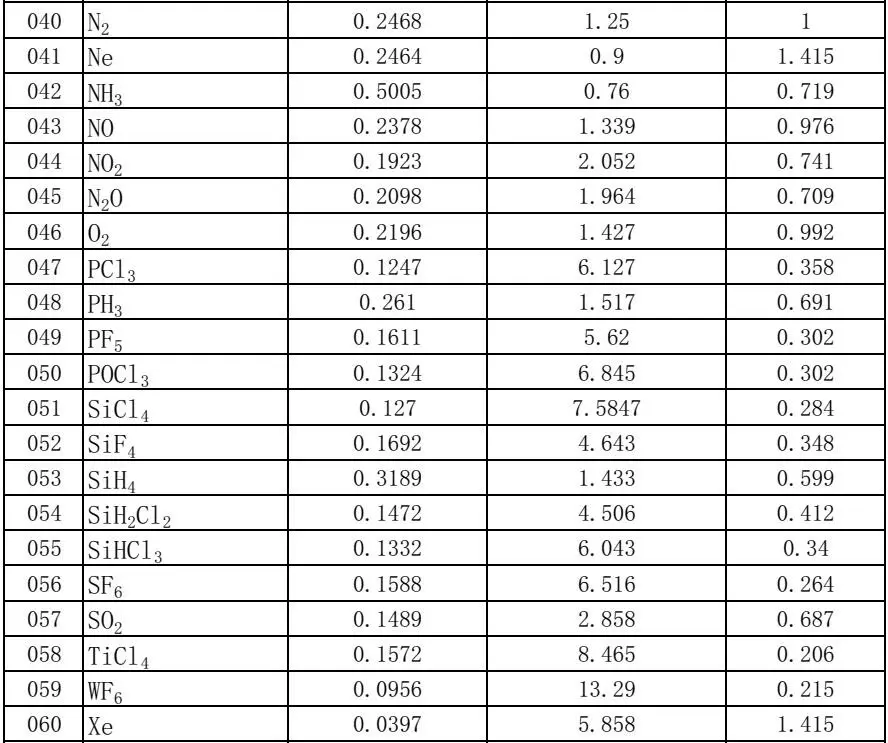

Gas conversion coefficient V2.0 | Gas conversion coefficient provides 60 Preloaded Gas Calibrations: See the following page for a complete list. If your application calls for a gas not on this list, please let us know. We can also calibrate to a wide variety of complex gas mixtures. |

Range Specific Specifications

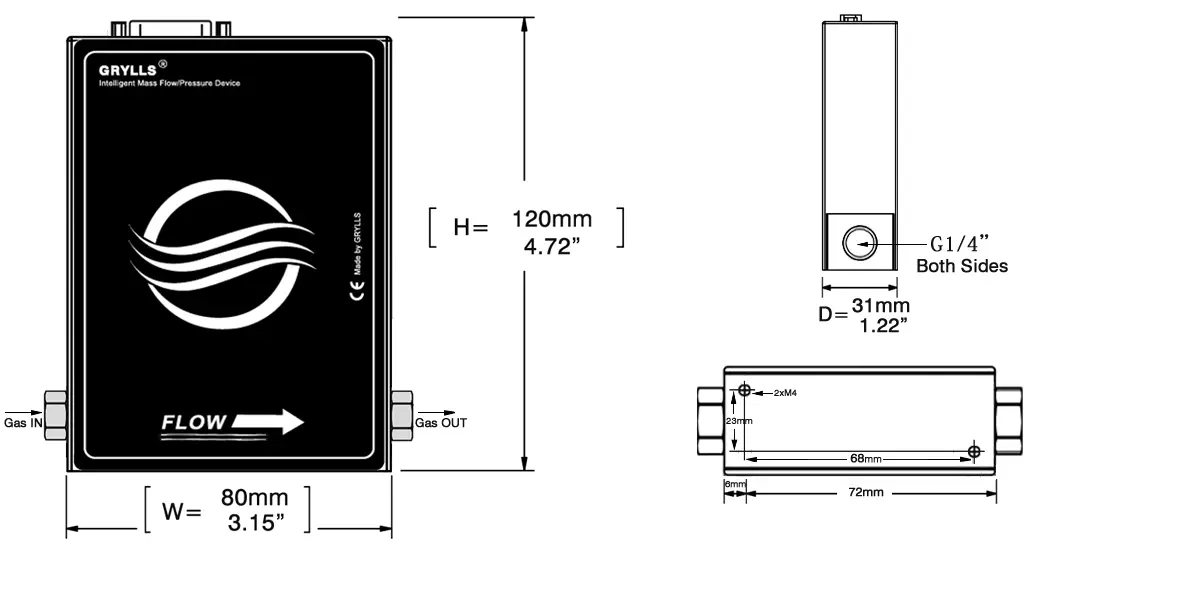

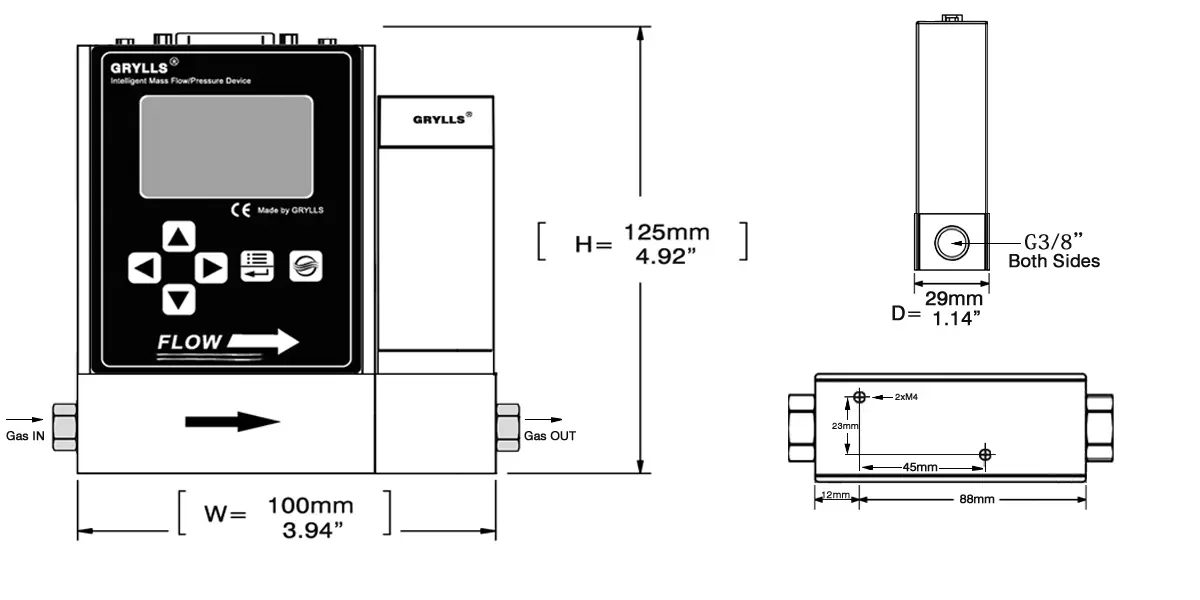

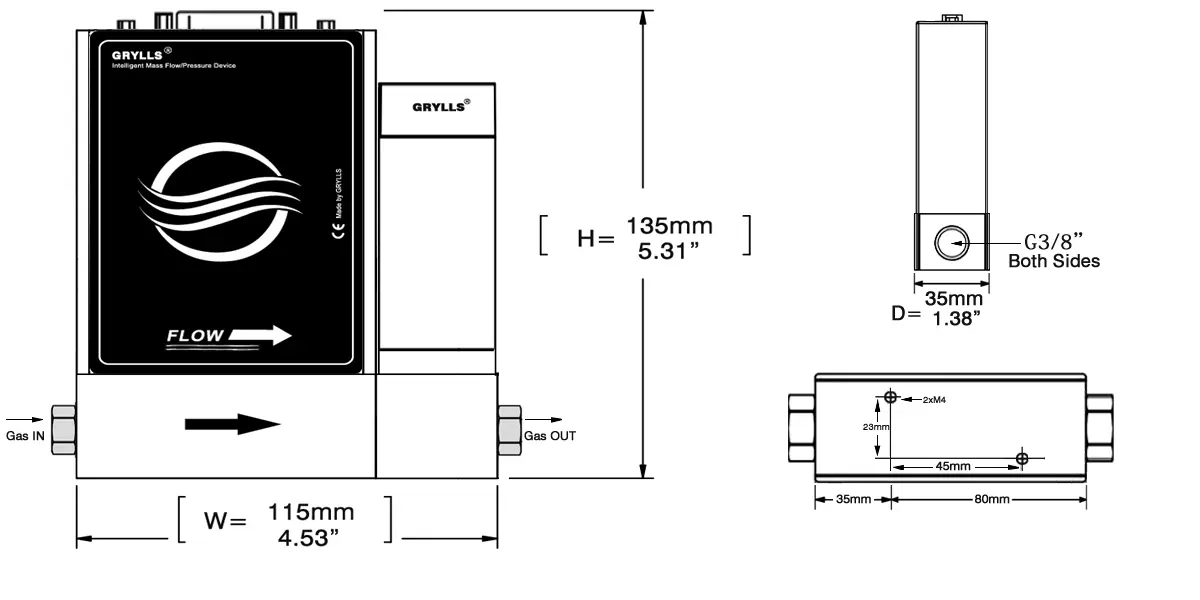

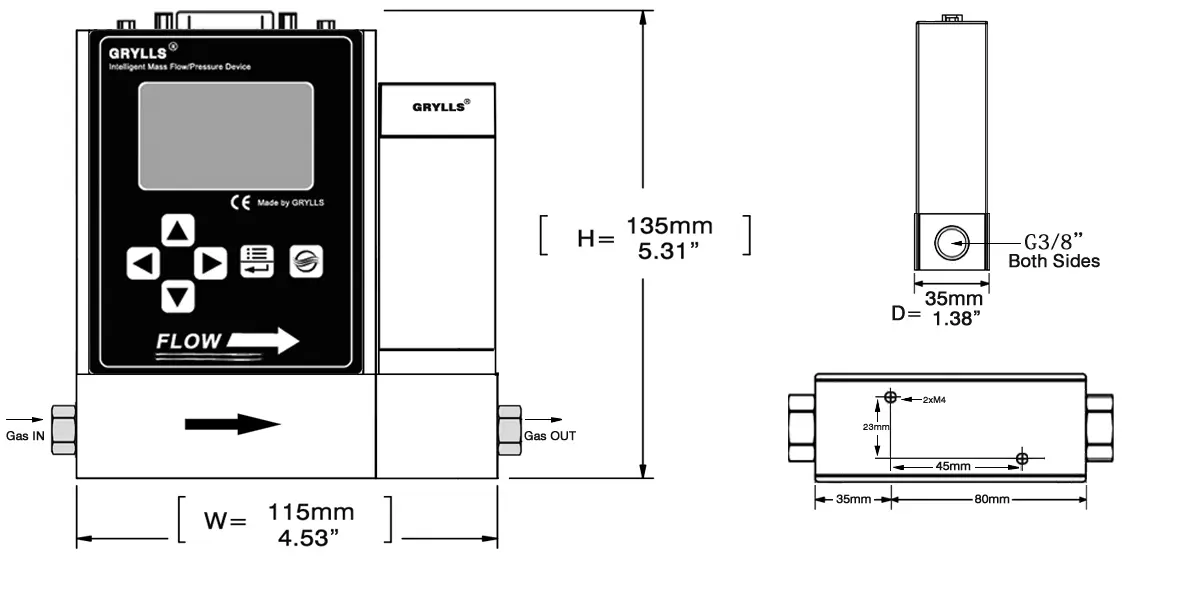

Full Scale Flow Mass Controller 1 | Mechanical Dimensions 2 | Process Connections3 |

GC-series 0.5-10 sccm |

GC-Standard series and Digital series 4.72”H x 3.15”W x 1.22”D

GC-Intelligent series 4.92”H x 3.94”W x 1.14”D |

G1/4” Female Thread

G3/8” Female Thread |

GC-series 10-100 sccm | ||

GC-series 100-500 scmm | ||

GC-series 500-1000 sccm | ||

GC-series 1000-2000 sccm | ||

GC-series 2-5 slm | ||

GC-series 5-20 slm | ||

GC-series 20-30 slm | ||

GC-series 30-100 slm |

5.31”H x 4.53”W x 1.38”D |

G3/8” Female Thread |

GC-series 100-200 slm | ||

GC-series 200-300 slm | ||

GC-series 300-500 slm |

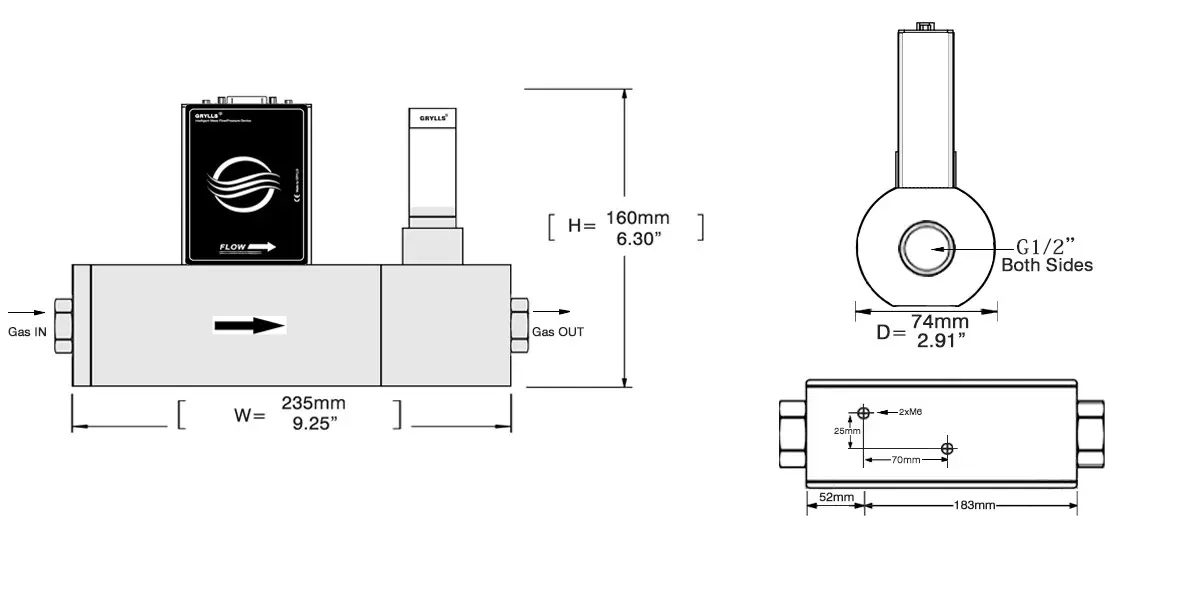

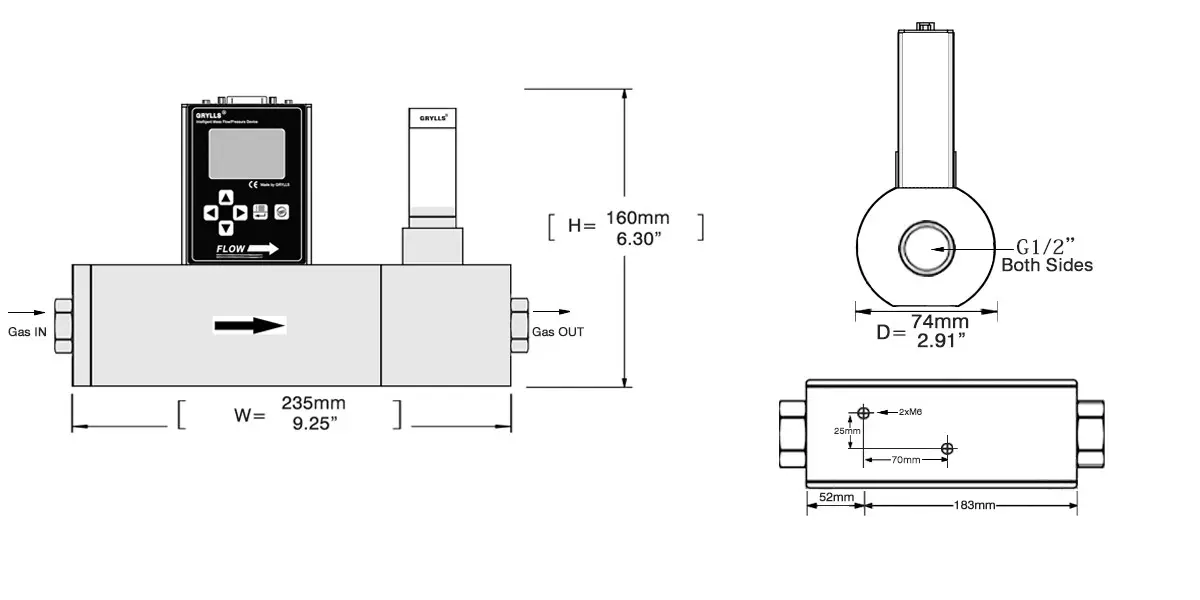

6.30”H x 9.25”W x 2.91”D |

G1/2” Female Thread |

GC-series 500-1000 slm | ||

GC-series 1000-2000 slm | ||

GC-series 2000-3000 slm | ||

GC-series 3000-6000 slm | 6.30”H x 9.25”W x 2.91”Dx2 | Double G1/2”Female Thread |

1. Lower Pressure Drops Available mass flow controllers please contact . 2. See drawings for metric equvalents. 3. Compatible with tube, face seal, push connect and compression adapter fittings. VCR and SAE connections upon request. | ||

GC- Standard series and Digital series

0.5sccm-30slm

GC- Intelligent series

0.5sccm- 30slm

GC- Standard series and Digital series

30slm-300slm

GC-Intelligent series

30slm-300slm

GC- Digital series 300slm-3000slm

GC- Intelligent series

300slm-3000slm

Appendix: Gas conversion coefficient V2.0

*For more single gas coefficients or mixed gas coefficients, please provide the specific heat and density of the gas medium and contact for calculation.

Quick Links

Contact Us

● Add:No. 8 building, 3rd. district,I-Town, Gaoli Zhang

road,Haidian District, Beijing, China 100095

● Contact :Zoe Pan

Skype: testifypp

● Mobile:+86 13601110505

● Whatsapp : +86 18600270515

● Email:info@bjsincerity.com